Dr. Despina A. Gkika

Hephaestus Laboratory

School of Chemistry-Faculty of Sciences

Democritus University of Thrace

GR 65404 Kavala, Greece

Email: degkika@chem.duth.gr

Sustainable production through the application of clean and environmentally friendly technologies

Examples of papers analyzing the sustainable production through the application of clean and environmentally friendly technologies:

D.A. Gkika, K. N. Maroulas, G.Z. Kyzas, Various Reduced Graphene Oxide Green Synthetic Routes: Comparing the Cost Procedures, ACS Omega, Aug. 2025 — doi:10.1021/acsomega.5c04090

.

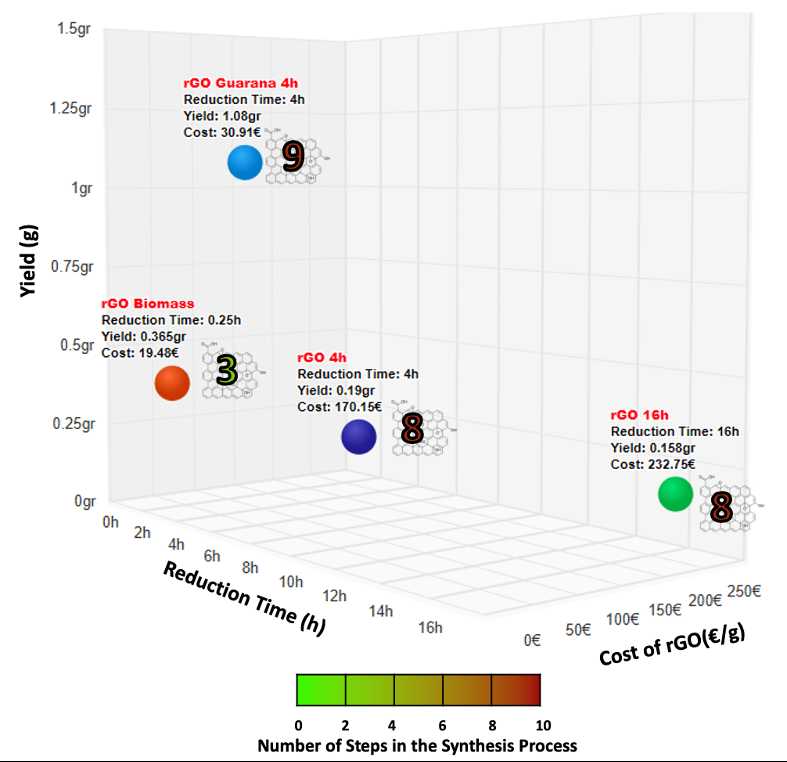

Synthesis cost is an unavoidable factor in synthetic pathways. Through four rGO synthesis routes compared the cost profiles of multi-step pathways and identified the most efficient synthetic route.

Biogenic or green-reduced graphene derivatives have emerged and found applications across diverse domains, including the detection of volatile organic compounds, biomedical uses, stretchable electronics, energy storage, photodetectors, high-contrast displays, and optoelectronic and photochemical technologies. These also encompass areas such as the degradation of waterborne pollutants and electrochemical systems like supercapacitors, lithium-ion storage devices, and various sensing applications. The synthesis of graphene and its derivatives frequently involves expensive and hazardous chemicals, posing risks to both the environment and human health. However, advancements in polymer composite research have increasingly fostered interdisciplinary collaboration among scientists, steering the field toward more sustainable practices. Previous empirical studies point out that the rising cost of synthesis is becoming an unavoidable factor in the design of new synthetic methodologies, although cost data is often scarce. One approach for the reduction of expenses is to streamline and optimize the synthesis process, such as by simplifying synthetic routes.The suitability of activity-based cost data for low-cost synthesis decisions, specifically for rGO, was assessed. Common methods involved complex, multi-step procedures with cumbersome preparation phases. First the synthesis is optimized by introducing guarana as a greener reducing agent. To further analyze cost and green considerations, the number of steps in the process was reduced from eight to three, resulting in time and cost savings. The most remarkable aspect of this new synthetic route is its simultaneous application of green chemistry principles and activity-based costing, which improves both the yield and sustainability of the key steps. Economically, compared to the common method costing 248.64 €/g (with eight steps), this streamlined approach cost 19.48 €/g (with three steps), mainly due to reductions in chemical and energy usage.

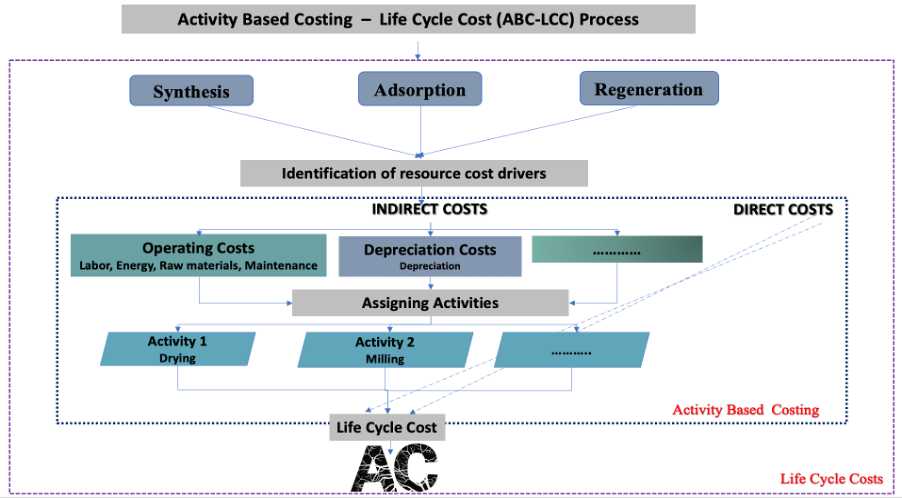

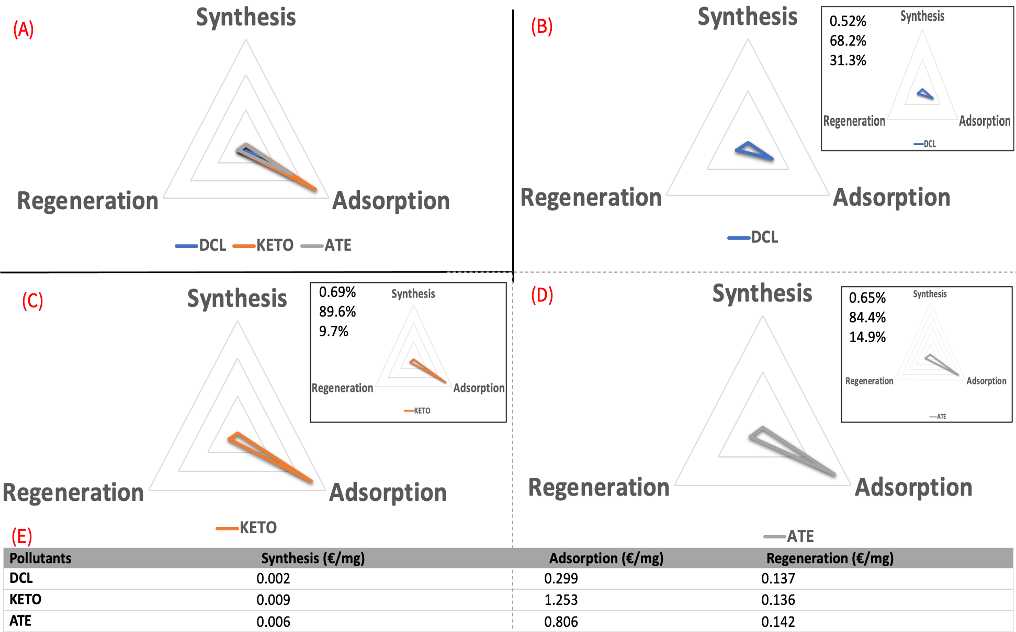

Despina A. Gkika and George Z. Kyzas Sustainable multi-functional life-cycle cost (LCC) framework for activated carbon materials: Linking synthesis procedure to adsorption performance.

Advancing technology drives the need for multifunctional materials, while global priorities demand that such performance be achieved through green chemistry to ensure truly sustainable development. Activated carbon (AC) in particular may satisfy these requirements thus scholars are investing considerable effort to translate AC cost-effective lab production. However, adsorption and synthesis protocols involve repetitive steps that add substantial costs to material development. This study introduces a multifunctional Activity based- Life cycle costing (ABC-LCC) methodology for waste-derived activated carbon, applied across three pollutants, diclofenac (DIC), ketoprofen (KETO), and atenolol (ATE). The method provides a multi-pollutant economic assessment at laboratory scale. Material costs, approximately 61.6%, are the largest contributor to synthesis LCC. Adsorption dominates the LCC for KETO, around 90%, while among the pollutants studied, only DIC shows a high regeneration percentage, approximately 31%. DIC is the most economical pollutant to remove, with a life-cycle cost of 0.43 €/mg, whereas KETO is the most expensive at 1.39 €/mg. The results show that environmental and economic performance share a common denominator: Qmax, the same adsorption capacity that determines pollutant removal efficiency also governs the life-cycle cost of treatment. Qmax therefore acts as the unifying factor that drives both sustainability and cost-effectiveness.

Despina A. Gkika and George Z. Kyzas Sustainable chitosan derivatives synthesis: On balancing cost and regeneration performance for dye adsorption.

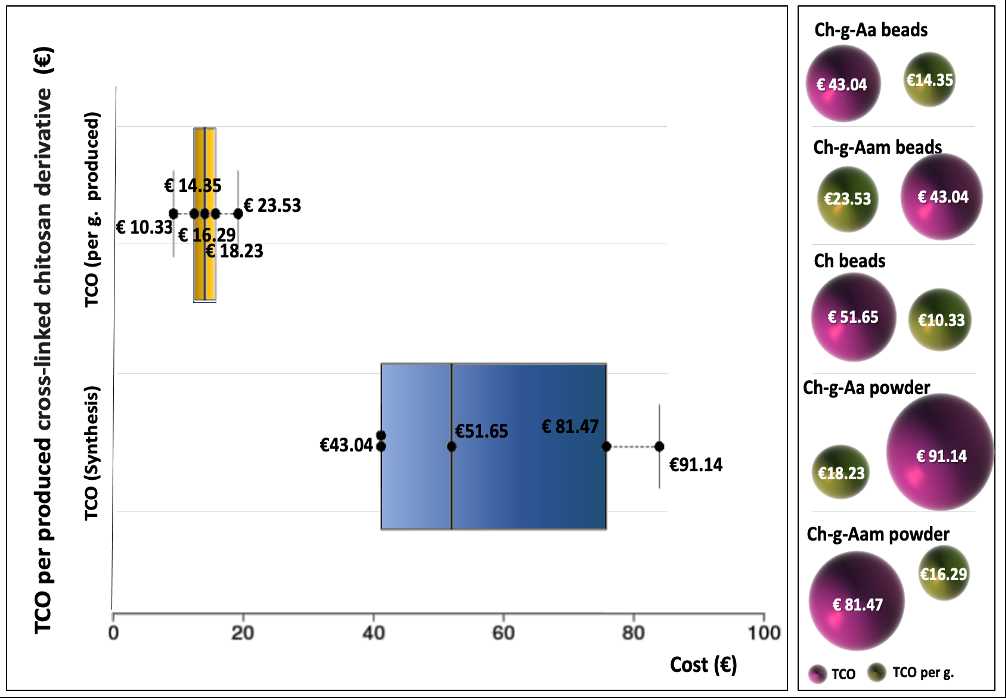

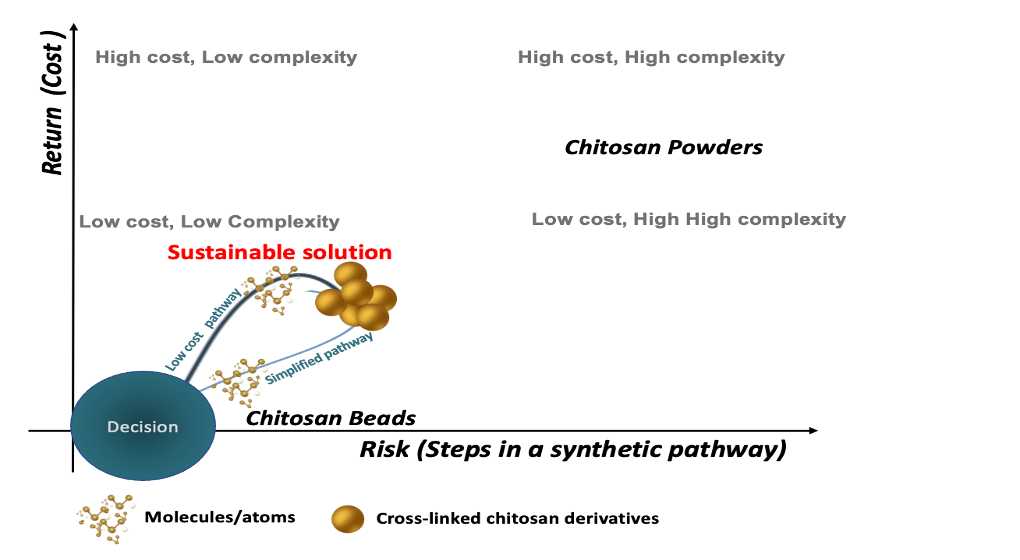

The widespread industrial use of chitosan derivatives underscores the necessity of evaluating the sustainability of their production processes. The innovative aspect of this study is rooted in its comprehensive methodological process, which integrates activity-based costing, total cost of ownership, and regeneration performance. A detailed evaluation of four case studies, examining both (Ch-g-Aa, Ch-g-Aam) powder and (Ch-g-Aa, Ch-g-Aam) bead forms, with a focus on environmental and economic dimensions. The cost breakdown per step reveals that the initial mixing of the solution for powders and magnetic stirring for beads (Step 1) is the primary contributor to the total synthesis cost. In contrast, for Ch-g-Aam, the dewatering stage (Step 4) represents the primary cost driver, reaching 37.53€. This underscores the significant economic impact of solvent consumption, particularly acetone. Economic analysis further confirmed their sustainability and feasibility, with laboratory-scale production costs of approximately 14.35€/g for Ch-g-Aa compared to 18.23€/g for Ch-g-Aa in powder form. The decision (risk) of synthetic pathway, driven either by performance or cost, govern the level of sustainability (return). The risk return profile revealed that the synthesized beads outperform all other scenarios, primarily due to their favorable balance between economic efficiency (low cost) and technical performance (high regeneration potential).